| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | JSSCD |

| Model Number : | JSSCD-230NC/P |

| Delivery Time : | 7-60 work days |

| Certification : | HB24Q00435R0S HB24E0025 HB24S00242R0S8R0S |

| Payment Terms : | FOB |

| Supply Ability : | 500 Sets Per Year |

JSSCD-230NC/P CNC High Speed Circular Saw Machine(Horizontal-Push)

Description

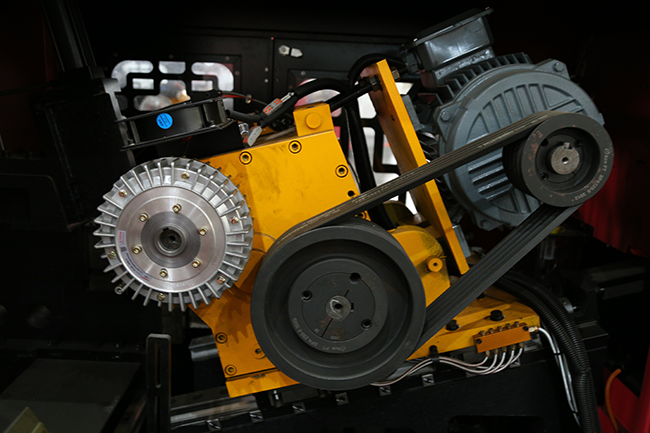

Engineered for demanding production lines, this horizontal CNC circular saw delivers rapid, high-accuracy cutting of metal profiles. Its combination of intelligent automation, precision engineering, and robust construction establishes it as a vital asset in modern metalworking, recognized for unwavering reliability.

Adaptive Processing & Cutting Integrity

The machine excels in processing diverse sections—including round

tubes, angle iron, and square stock—through its multi-directional

hydraulic clamping system (horizontal/vertical). This adaptive

fixturing drastically reduces setup changes, enhancing flexibility

across varied material dimensions and shapes. Cutting stability is

ensured by an advanced horizontal plunge mechanism, driven by an AC

servo motor and ball screw assembly. High-strength construction and

precision engineering in the drive and clamping systems securely

immobilize workpieces during high-velocity operation. This

eliminates vibration and guarantees consistent, repeatable cut

accuracy, making it indispensable for continuous, high-volume

production where stability is paramount.

Intelligent Control & Streamlined Operation

Central to the system is a sophisticated CNC control module,

functioning as the operational "brain". It enables meticulous

adjustment of critical parameters like cutting speed and angle for

efficient, precise outcomes that meet stringent tolerances.

Integration with a user-friendly Human-Machine Interface (HMI)

simplifies programming. Operators can easily input cutting

sequences and store numerous job configurations, enabling fully

automated processing. This significantly reduces manual

intervention and potential errors.

Specifications:

| Model | Unit | JSSCD-230NC/P |

| Mainframe dimensions | mm | 2600*2700*2300 |

| Bar & round pipe | mm | 80-230 |

| Angle bar & square bar | mm | 80-200 |

| Saw blade size | mm | φ630*3.4*φ80 |

| Pin holes and hole diameters | mm | 4*φ24*150 φ80 |

| Spindle motor power | KW | 30(6P) |

| Spindle speed | rpm | 20-80 |

| Feed servo motor power | KW | 7.5 |

| Feeding servo motor power | KW | 3.5 |

| Material removal length at the front end | mm | 20-99 |

| Single feeding length(repeatable) | mm | 10-800 |

| Hydraulic drive motor power | KW | 5.5 |

| Rated pressure of the hydraulic system | mpa | 5.5 |

| Hydraulic oil capacity | L | 150 |

| Cut off feed mode | AC servo motor & ball screw / horizontal entry | |

| Main clamping method | Hydraulic type / one set each for horizontal and 15° | |

| Saw blade debris removal device | Passive/active circular wire brush (optional) | |

| Gear backlash compensation device | Hollow external rotating magnetic powder brake | |

| Feeding drive mode | AC servo motor & ball screw | |

| Feeding clamp method | Hydraulic type/Horizontal clamping | |

| Residual material length at the rear end | mm | 90&a(a represents the length less than one cut-off workpiece) |

| Self-lubrication oil system | Timed and quantitative forced oil supply | |

| Micro-lubrication system for cutting | Quasi-dry intermittent oil supply | |

| Material separating device | Pneumatic reciprocating | |

| Long material receiving device | Optional | |

| Blade swing anti-vibration device | Tungsten carbide parallel block |

Enhanced Automation & Sustained Performance

An optional high-capacity automatic feeder supports uninterrupted

material supply. Synergizing with the horizontal cutting mode, it

enables seamless batch processing, maximizing machine utilization

and output capacity for large-scale, rapid production. Long-term

precision is maintained by a gear backlash compensator (AC servo

motor + ball screw). A robust hydraulic system (stable pressure,

ample reservoir) energizes the clamping and specific drive

functions. Critical component durability is extended via a

self-lubrication system (timed, metered oil delivery) and a tool

micro-lubrication unit (pneumatic reciprocating, quasi-dry

intermittent oiling). Workspace cleanliness and equipment

protection are ensured by a saw blade chip extraction device

(hollow external rotating magnetic powder brake), improving

operational safety. Neat separation of cut pieces is achieved by a

material divider (carbide parallel blocks).

Driving Efficiency in Modern Manufacturing

This Horizontal High-Speed Circular Saw adeptly balances

high-volume continuous throughput with rigorous precision

requirements. It represents the optimal solution for businesses

targeting enhanced productivity, superior part quality, and reduced

operational expenditure. By leveraging intelligent operation, rapid

horizontal cutting technology, and optional automation, the

equipment increases material utilization, minimizes waste, shortens

cycle durations, and decreases labor dependence. For metal

processors committed to boosting competitiveness and progressing

towards intelligent manufacturing, this robust, efficient, and

smart horizontal saw is the premier choice for contemporary

workshops, delivering significant contributions to sustainable

growth and operational excellence.

FAQ

Q1: Are you a manufacturer or a trading company?

A:We are a professional manufacturer of saw blade grinders. We have a 30,000 square meter factory and a team of dedicated technicians specializing in design, manufacturing, and sales.

Q2. Where is your factory located?

A:Our factory is located in Nantong City, Jiangsu Province, China.

It will takes about 1.5 hours from Shanghai Hongqiao station to our city

Q3: What is your factory acceptance test method?

A: You can send us sample material to be cut, and we will perform a test cut using our machine. After the test is complete, we will provide you with detailed cutting data. (We will also send you a video of the machine cutting operation for your confirmation.)

Q4:What is your method of transaction?

A:We adopt the FOB(Free ON Board) transaction.

Q5: How about your delivery time?

A: Generally, it will take 7-60 work days after receiving your order.

The specific delivery time depends on the items and the quantity of your order.

Q6:How about the payment term

A:T/T 30% deposit, 70% of balance paid before shipment. (For other payment methods please contact our sales team)

Q7:Does the band saw blade have any international certifications?

A:Yes,we have obtained CE,ISO international certification.

|