| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | JSSCD |

| Model Number : | JSSCD-100NC/X |

| Certification : | HB24Q00435R0S HB24E0025 HB24S00242R0S8R0S |

| Delivery Time : | 7-60 work days |

| Payment Terms : | FOB |

| Supply Ability : | 500 Sets Per Year |

JSSCD-100NC/X CNC High Speed Circular Saw for Metal Cutting

Description

In the competitive realm of metal fabrication—where precision and throughput are paramount—this advanced CNC high-speed circular saw delivers significant operational advantages. Its core capability lies in executing precise angular cuts across a broad spectrum. The signature innovation is a dedicated 15-degree downward cutting trajectory. Combined with rapid processing, intelligent automation, exceptional accuracy, and sustainable engineering, it forms a high-productivity cornerstone for modern industrial environments.

The system efficiently processes diverse metal profiles, such as tubing and structural shapes. Its optimized construction enhances processing flexibility, substantially reducing the need for repeated fixture changes due to variations in material size or geometry. This allows seamless adaptation to fluctuating cutting requirements.

The 15-degree downward cutting mechanism constitutes its primary technical breakthrough. This design strategically redirects cutting pressures, markedly diminishing impact forces on the workpiece. The result is consistently smooth, flat cut surfaces—a critical attribute for applications demanding superior edge quality.

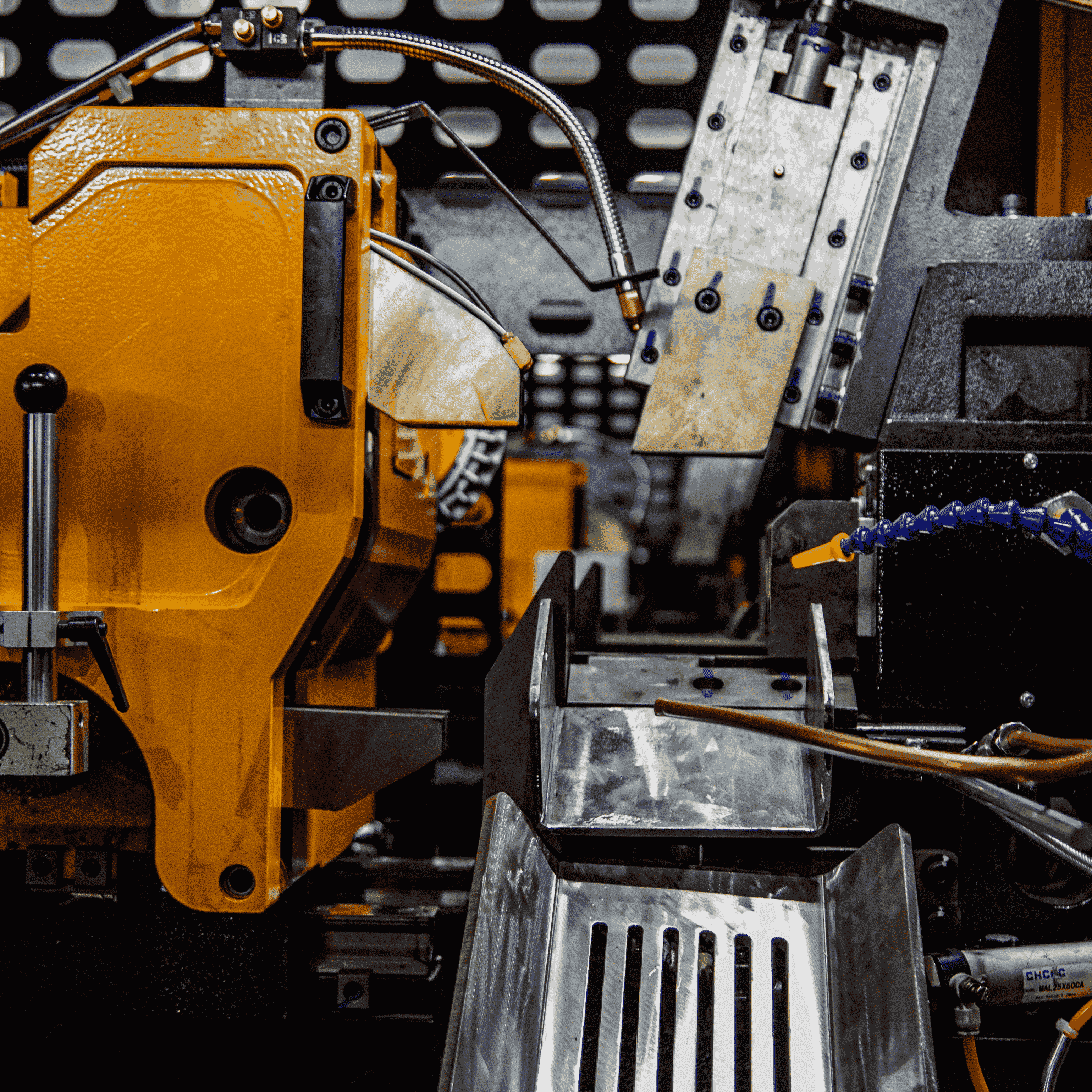

Integration of a high-performance drive system and a rigid clamping apparatus ensures dependable workpiece fixation. Precision engineering guarantees part immobilization, even under the intense dynamic stresses of high-velocity cutting. This stability underpins consistent process outcomes and repeatable results.

Central to operation is a sophisticated intelligent controller. This unit precisely regulates vital parameters—including feed rates and cutting angles—to ensure swift, accurate execution strictly adhering to programmed specifications. The integrated high-precision CNC system features an intuitive HMI interface. Operators can effortlessly preconfigure cutting sequences and archive multiple operational programs, facilitating fully automated workflows. This significantly reduces manual intervention while mitigating potential processing errors.

Specification

Model | Unit | JSSCD-100NC/X |

| Mainframe dimensions | mm | 2230*1800*1890 |

| Bar & round pipe | mm | 20-100 |

| Angle bar & square bar | mm | 20-85 |

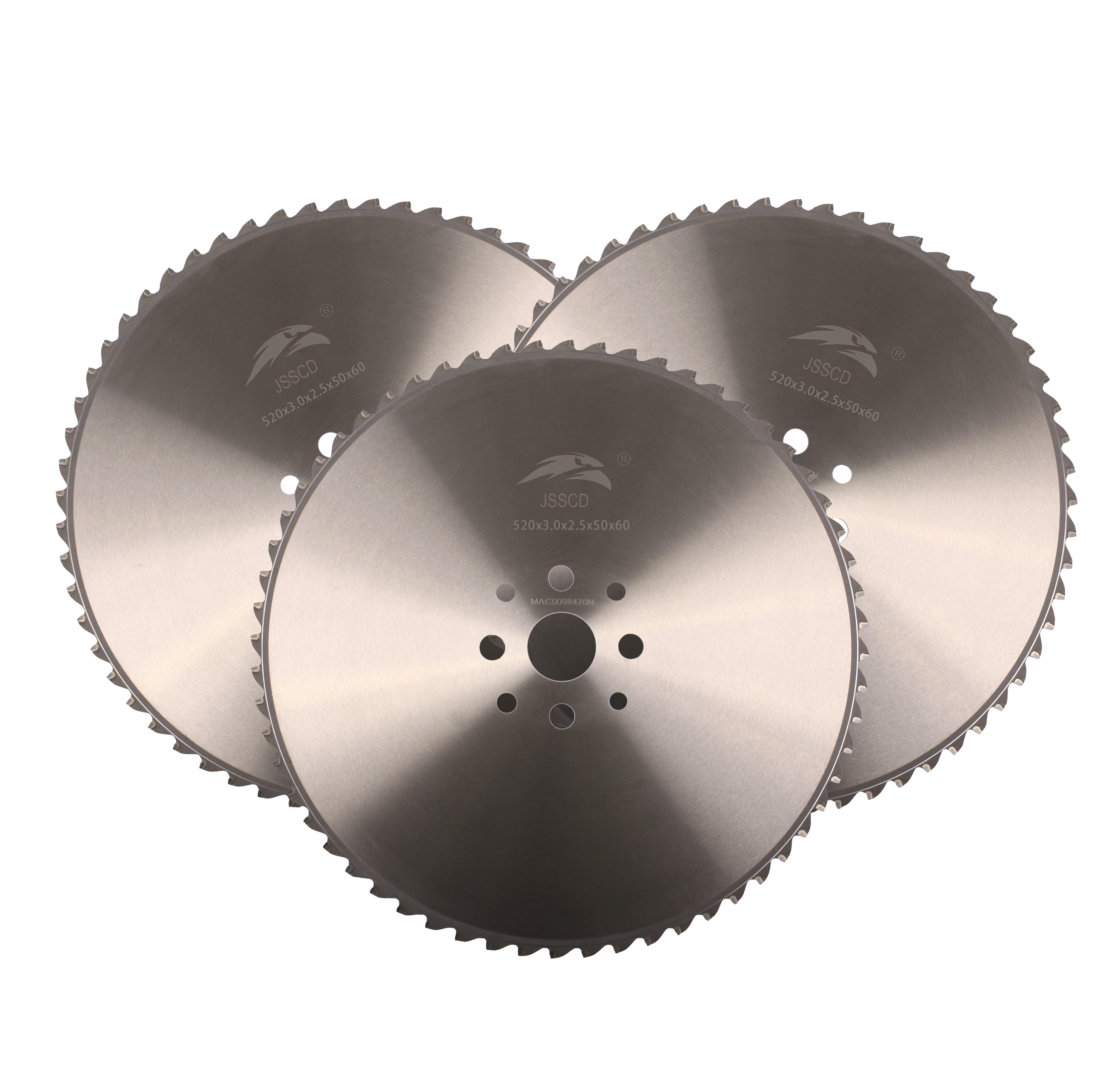

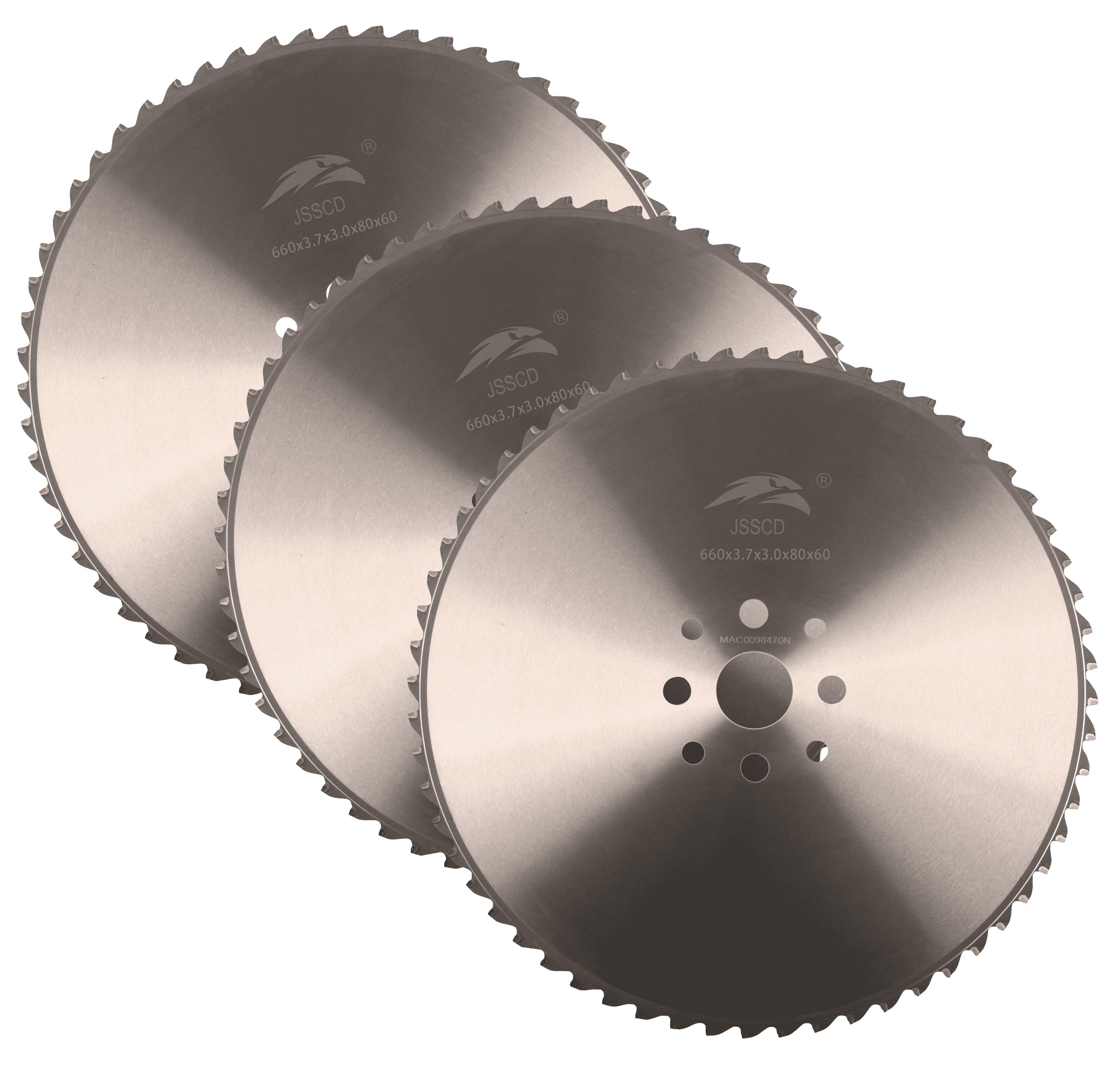

| Saw blade size | mm | φ360*2.6*φ40 |

| Pin holes and hole diameters | mm | 4*φ11*90 φ40 |

| Spindle motor power | KW | 11(4p) |

| Spindle speed | rpm | 20-140 |

| Feed servo motor | KW | 2 |

| Feeding servo motor | KW | 2 |

| Material removal length at the front end | mm | 10-99 |

| Single feeding length(repeatable) | mm | 10-800 |

| Hydraulic drive motor power | KW | 2.25(4p) |

| Rated pressure of the hydraulic system | mpa | 5.5 |

| Hydraulic oil capacity | L | 100 |

| Cut off feed mode | AC servo motor & ball screw / 15° cutting-in | |

| Main clamping method | Hydraulic type / one set each for horizontal and15° | |

| Saw blade debris removal device | Passive / active circular wire brush (optional) | |

| Gear backlash compensation device | Hollow external rotating magnetic powder brake | |

| Feeding drive mode | AC servo motor & ball screw | |

| Feeding clamp method | Hydraulic type / Horizontal clamping | |

| Residual material length at the rear end | mm | 85&a(a represents the length less than one cut-off workpiece) |

| Self-lubrication oil system | Timed and quantitative forced oil supply | |

| Micro-lubrication system for cutting | Quasi-dry intermittent oil supply | |

| Material separating device | Pneumatic reciprocating | |

| Long material receiving device | Optional | |

| Blade swing anti-vibration device | Tungsten carbide parallel block |

For high-volume scenarios, an optional automated material handling system is available. This addition enables continuous batch processing, extending operational uptime. This capability elevates productivity, directly supporting ambitious output targets.

This equipment successfully balances the dual imperatives of mass production and meticulous machining. It serves as a strategic asset for businesses seeking enhanced throughput and superior finish quality, delivering steadfast cutting performance. Through intelligent control synergized with high-velocity cutting, it effectively:

Improves material utilization

Reduces waste generation

Accelerates cycle times

Shortens delivery schedules

Optimizes labor deployment

For metal fabricators focused on market advancement, this machine represents an optimal solution for pursuing sustainable expansion and modernizing production infrastructure, driving significant operational progress.

FAQ

Q1: Are you a manufacturer or a trading company?

A:We are a professional manufacturer of saw blade grinders. We have a 30,000 square meter factory and a team of dedicated technicians specializing in design, manufacturing, and sales.

Q2. Where is your factory located?

A:Our factory is located in Nantong City, Jiangsu Province, China.

It will takes about 1.5 hours from Shanghai Hongqiao station to our city

Q3: What is your factory acceptance test method?

A: You can send us sample material to be cut, and we will perform a test cut using our machine. After the test is complete, we will provide you with detailed cutting data. (We will also send you a video of the machine cutting operation for your confirmation.)

Q4:What is your method of transaction?

A:We adopt the FOB(Free ON Board) transaction.

Q5: How about your delivery time?

A: Generally, it will take 7-60 work days after receiving your order.

The specific delivery time depends on the items and the quantity of your order.

Q6:How about the payment term

A:T/T 30% deposit, 70% of balance paid before shipment. (For other payment methods please contact our sales team)

Q7:Does the band saw blade have any international certifications?

A:Yes,we have obtained CE,ISO international certification.

|