| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | JSSCD |

| Model Number : | JSSCD-100NC/P |

| Delivery Time : | 7-60 work days |

| Certification : | HB24Q00435R0S HB24E0025 HB24S00242R0S8R0S |

| Payment Terms : | FOB |

| Supply Ability : | 500 Sets Per Year |

JSSCD-100NC/P CNC High Speed Circular Saw Machine(Horizontal-Push)

Description

Intensive horizontal metal cutting operations face the critical challenge of achieving both substantial output and uncompromising dimensional precision. This CNC high-speed circular saw delivers a strategic solution, combining rapid cutting capability, sophisticated control, exceptional accuracy, and sustainable operation. Designed for robust performance and long-term consistency, it stands as a cornerstone technology for contemporary metal fabrication.

Engineering Excellence for Sustained Accuracy

The machine's core strength is its consistent precision throughout extended production cycles. This reliability stems from several key features:

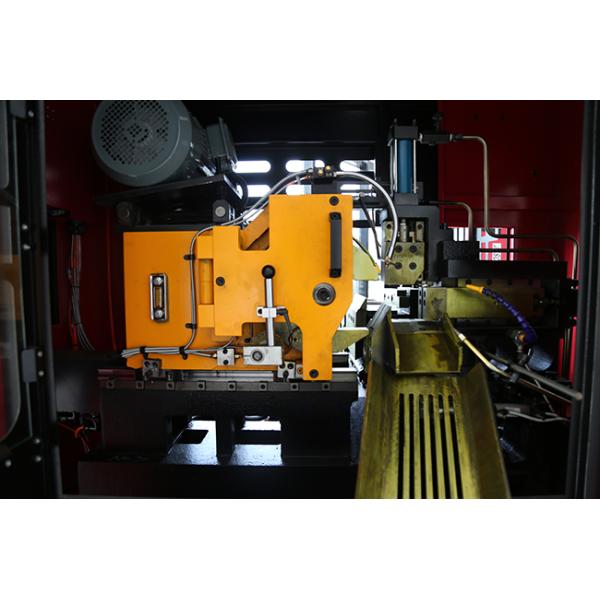

Advanced Horizontal Feed Cutting: Utilizing an AC servo motor and ball screw transmission, this system enables smooth, operator-controlled cutting motions.

High-Efficiency Material Fixation: A hydraulic multi-axis clamping system secures workpieces firmly. This design drastically reduces changeover time when adjusting for different material sizes or shapes, boosting operational agility. Critical structural elements are precision-engineered from resilient materials, guaranteeing absolute workpiece stability even during aggressive cutting, eliminating slippage. The result is repeatable, high-fidelity cuts vital for continuous manufacturing standards.

Long-Term Precision Assurance: Dimensional stability is ensured by backlash minimization in the servo/ball screw drive. A powerful hydraulic system maintains uniform clamping and feed pressure. An integrated lubrication strategy – featuring a smart central system (timed/dosed) plus a pneumatic MQL unit for blade cooling – significantly lowers wear on vital components, prolonging maintenance intervals. A magnetic chip removal system (using a hollow rotary brake) keeps the workspace cleaner, enhancing safety and accessibility. Clean part ejection is facilitated by a tungsten-carbide separator.

Boosting Productivity Through Automation & Control

For facilities prioritizing elevated throughput, an optional HIGH-CAPACITY AUTOMATED MATERIAL HANDLING SYSTEM integrates seamlessly. This system provides continuous, automated

feeding, synchronizing perfectly with the saw's horizontal action.

It enables extended, unattended batch processing, maximizing

equipment uptime and overall production line output to meet

rigorous large-scale schedules.

Specifications:

| Model | Unit | JSSCD-100NC/P |

| Mainframe dimensions | mm | 2230*1800*1890 |

| Bar & round pipe | mm | 20-100 |

| Angle bar & square bar | mm | 20-85 |

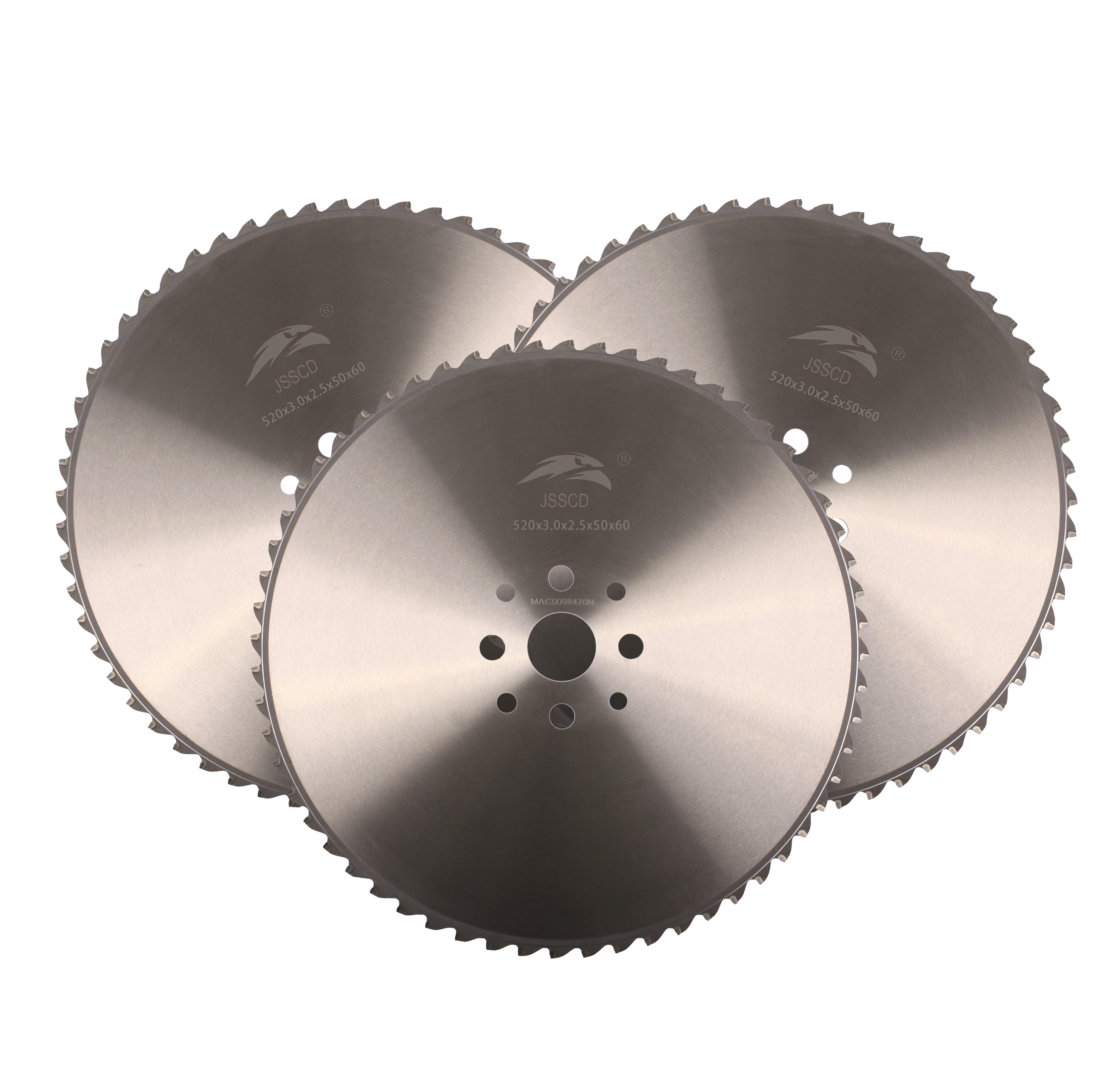

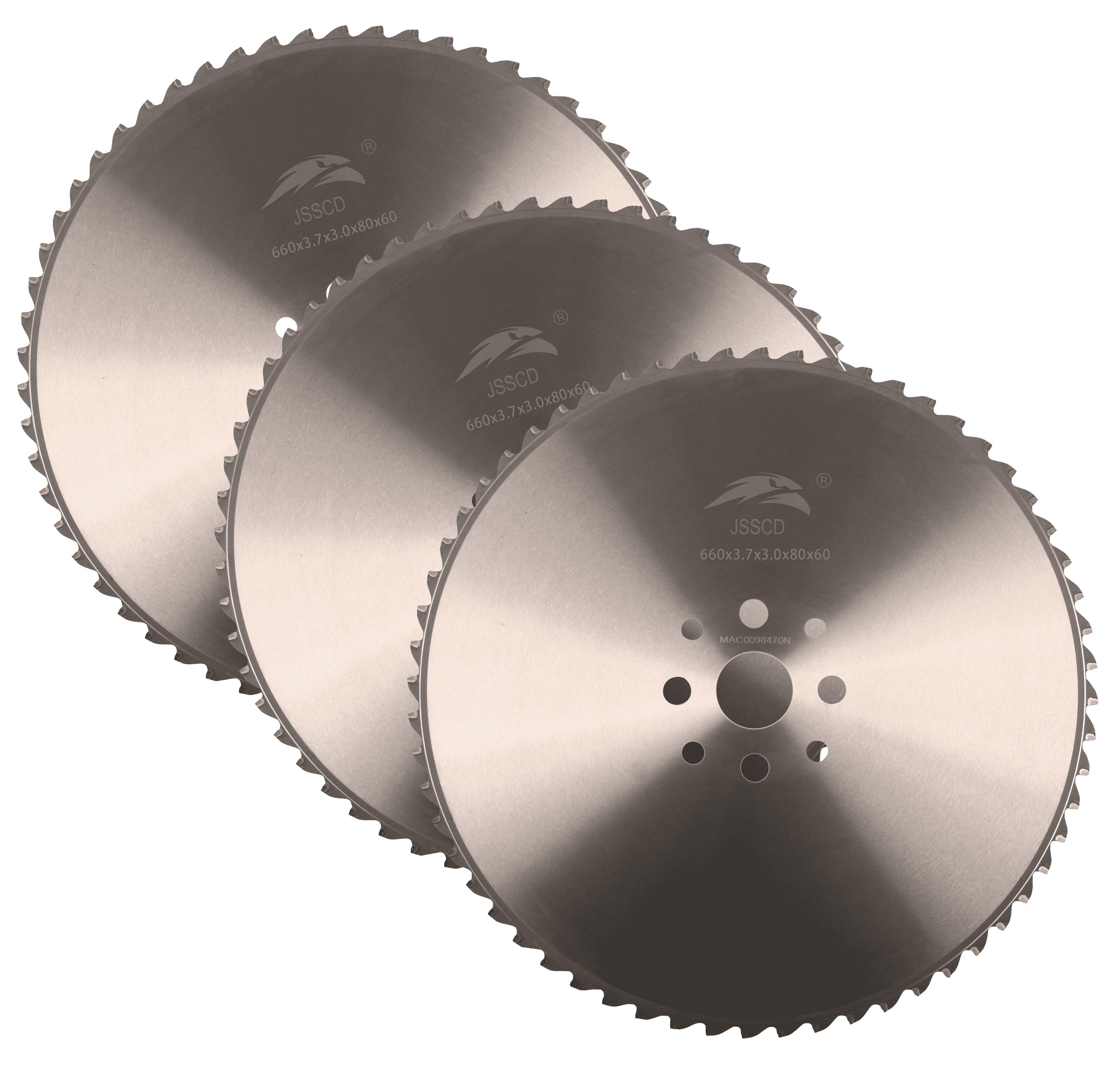

| Saw blade size | mm | φ360*2.6*φ40 |

| Pin holes and hole diameters | mm | 4*φ11*90 φ40 |

| Spindle motor power | KW | 11(4P) |

| Spindle speed | rpm | 20-140 |

| Feed servo motor power | KW | 2 |

| Feeding servo motor power | KW | 2 |

| Material removal length at the front end | mm | 10-99 |

| Single feeding length(repeatable) | mm | 10-800 |

| Hydraulic drive motor power | KW | 2.25(4p) |

| Rated pressure of the hydraulic system | mpa | 5.5 |

| Hydraulic oil capacity | L | 100 |

| Cut off feed mode | AC servo motor & ball screw / horizontal entry | |

| Main clamping method | Hydraulic type / one set each for horizontal and 15° | |

| Saw blade debris removal device | Passive/active circular wire brush (optional) | |

| Gear backlash compensation device | Hollow external rotating magnetic powder brake | |

| Feeding drive mode | AC servo motor & ball screw | |

| Feeding clamp method | Hydraulic type/Horizontal clamping | |

| Residual material length at the rear end | mm | 90&a(a represents the length less than one cut-off workpiece) |

| Self-lubrication oil system | Timed and quantitative forced oil supply | |

| Micro-lubrication system for cutting | Quasi-dry intermittent oil supply | |

| Material separating device | Pneumatic reciprocating | |

| Long material receiving device | Optional | |

| Blade swing anti-vibration device | Tungsten carbide parallel block |

User-Centric Operation

Commanding the machine is a PRECISION CNC CONTROL SYSTEM. This unit meticulously governs essential parameters like cutting

velocity and angular positioning, guaranteeing efficient and

accurate results for every part. Paired with an intuitive

Human-Machine Interface (HMI), operation is remarkably simple.

Production personnel can easily input settings and archive numerous

cutting programs via the straightforward console, achieving a high

degree of automation. This drastically reduces operator workload

and minimizes the risk of errors associated with manual

adjustments.

The Strategic Edge in Advanced Metalworking

This high-output horizontal circular saw effectively tackles the

dual pressures of serial production volume and precision cutting

requirements. It represents the optimal investment for businesses

focused on elevating production rates, enhancing part quality, and

reducing operational expenditures. By merging intelligent CNC

technology, advanced horizontal cutting mechanics, and adaptable

automation, the system improves material yield, minimizes scrap,

accelerates cycle times, and reduces reliance on manual

intervention. For metal processors dedicated to building a

competitive edge and advancing towards intelligent manufacturing,

this dependable, high-efficiency, smart horizontal circular saw

serves as foundational equipment for the modern facility, driving

superior operational outcomes and sustainable growth.

FAQ

Q1: Are you a manufacturer or a trading company?

A:We are a professional manufacturer of saw blade grinders. We have a 30,000 square meter factory and a team of dedicated technicians specializing in design, manufacturing, and sales.

Q2. Where is your factory located?

A:Our factory is located in Nantong City, Jiangsu Province, China.

It will takes about 1.5 hours from Shanghai Hongqiao station to our city

Q3: What is your factory acceptance test method?

A: You can send us sample material to be cut, and we will perform a test cut using our machine. After the test is complete, we will provide you with detailed cutting data. (We will also send you a video of the machine cutting operation for your confirmation.)

Q4:What is your method of transaction?

A:We adopt the FOB(Free ON Board) transaction.

Q5: How about your delivery time?

A: Generally, it will take 7-60 work days after receiving your order.

The specific delivery time depends on the items and the quantity of your order.

Q6:How about the payment term

A:T/T 30% deposit, 70% of balance paid before shipment. (For other payment methods please contact our sales team)

Q7:Does the band saw blade have any international certifications?

A:Yes,we have obtained CE,ISO international certification.

|